400-9988-900

400-9988-900

400-9988-900

400-9988-900

In the pharmaceuticalindustry, precise liquid metering equipment plays a crucial role in qualitycontrol during the production process and product consistency insurance.Ceramic metering pumps, as an advanced solution for liquid transfermeasurement, seamlessly integrate precision engineering, safety, stability, anddurability. Leveraging its unique performance and advantages, ceramic meteringpumps find widespread application in the pharmaceutical sector.

● Why is the ceramicmetering pump considered the "heart" of aseptic liquid filling?

In the entire process of asepticliquid filling, the metering and filling stage is the only process involvingmechanical friction and interaction with sterile liquids. Therefore, ensuringthe precision and safety of the metering components is a crucial control factorfor minimizing the risks associated with aseptic filling. The performance ofceramic metering pumps directly determines the safety and stability of thecustomer's product, making it an essential aspect of maintaining quality inaseptic liquid filling processes.

● The Working Principle ofCeramic Metering Pumps

A ceramic metering pumpis a device designed to precisely transfer liquids through the precise movementof a plunger, achieving accurate metering. Inside the pump, the plungerundergoes precise reciprocating motion driven by a motor, thereby altering thevolume of the pump chamber and facilitating the suction and discharge of theliquid. Due to the ability to precisely control the speed and direction of theplunger's movement through the motor, ceramic metering pumps can achieve highlyaccurate liquid metering.

● The Key Technical Features of Ceramic Metering Pumps

1. High Precision

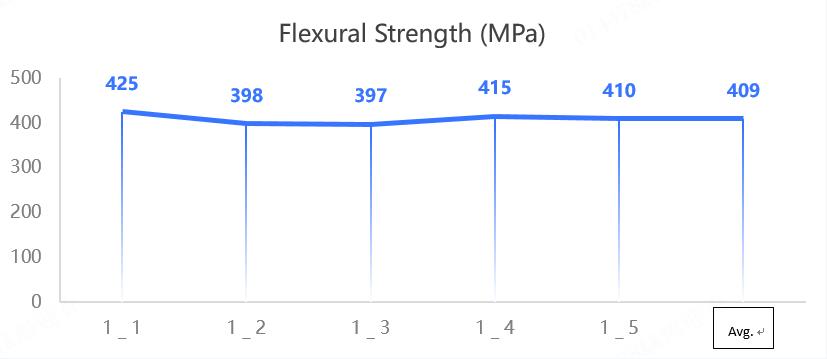

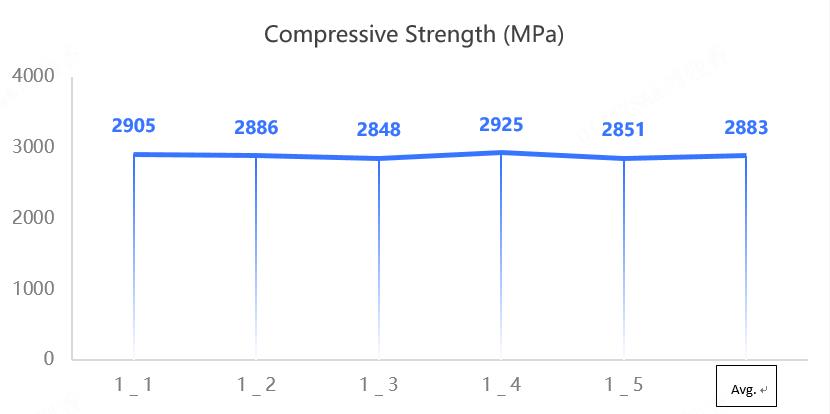

The fundamental characteristic of ceramic metering pumps lies in their highprecision, as precision is paramount for a metering product. The ceramic pumpis required to maintain a metering accuracy error within ±5‰. This highprecision is manifested in several dimensions:

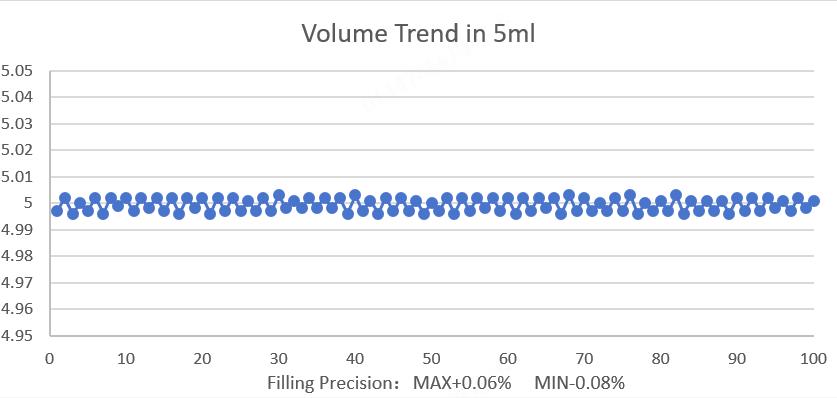

(1) Filling accuracy of a single drug under a specific filling condition;

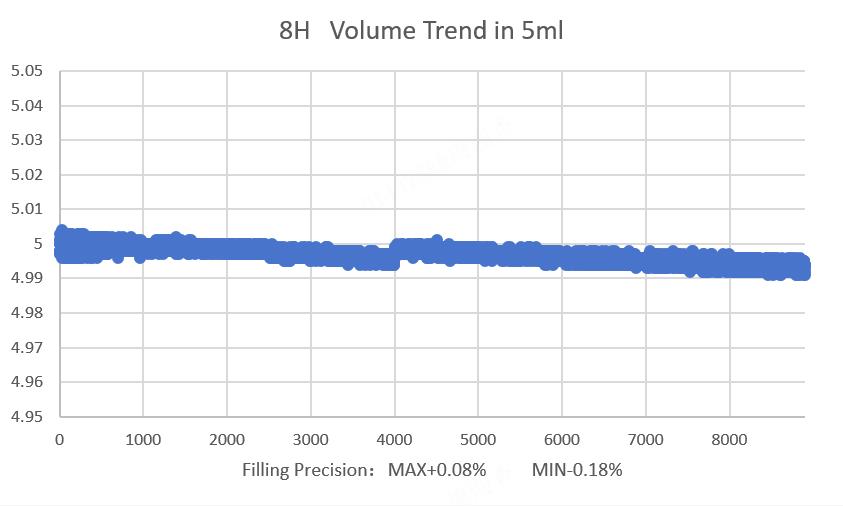

(2) In the context of asingle production cycle and specific filling measurement requirements for acertain process, the precision of filling measurements is evaluated in terms offluctuation accuracy.

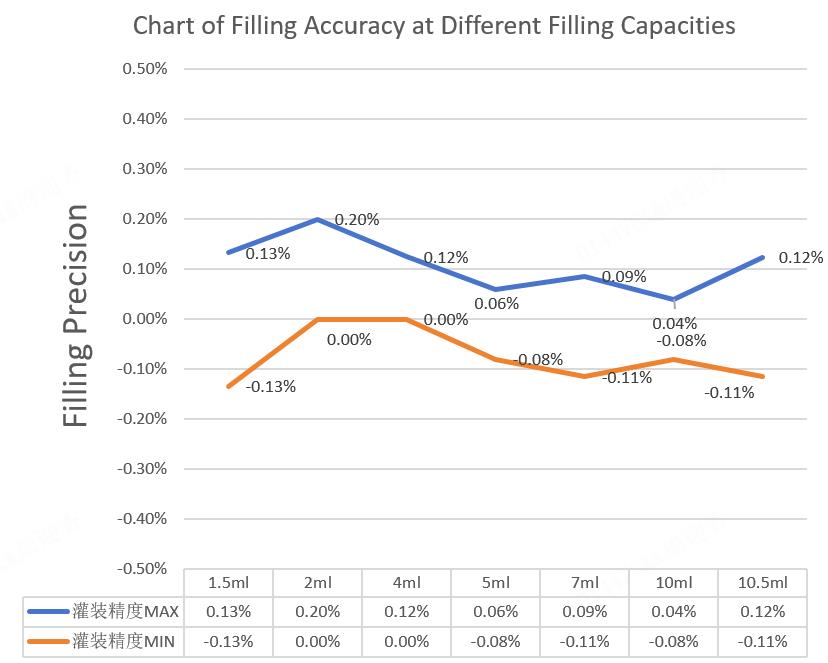

(3) The fluctuation accuracy ofmeasurement precision under different filling measurement requirements withinthe measurement range.

|

|

(4) Under variousviscosity and pH conditions, the measurement fluctuation accuracy of fillingprecision.

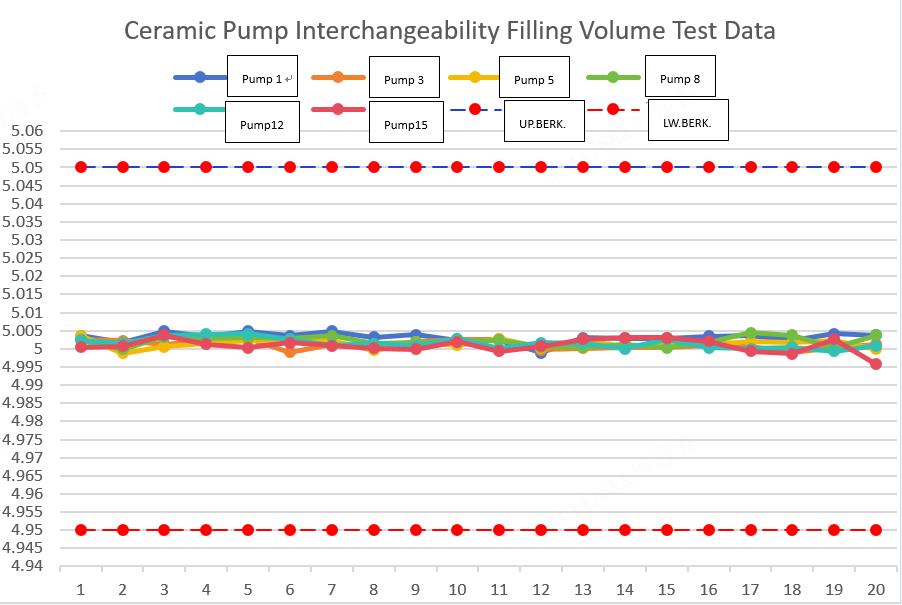

2. Consistency in Product Performance

(5) In pharmaceutical filling equipment, ceramicmetering pumps are not employed as standalone units but rather as part of alarger system comprising 6 to 12, or even more, pump units integrated into acomplete filling system. Therefore, the consistency in the product performanceof ceramic metering pumps is pivotal, as it directly influences the tunabilityof manufacturing filling equipment. This consistency ensures that each fillingpoint in the filling system can share a set of control process parameters,facilitating precise metering and filling. The adherence to a uniform set ofparameters guarantees the verifiability of the filling equipment, making it anessential characteristic of ceramic metering pumps.

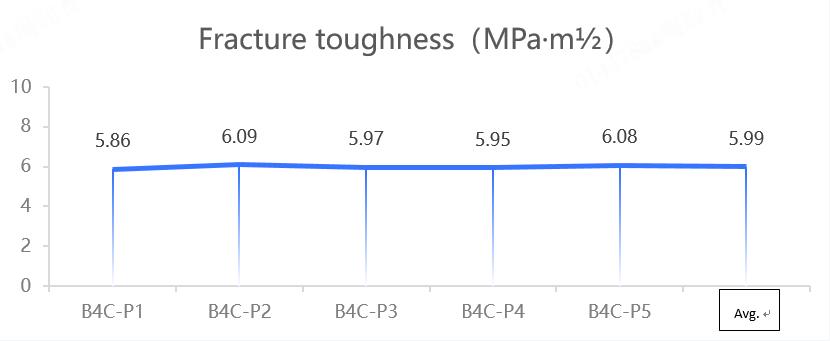

3. Safety of Ceramic Materials

Theuse of ceramic materials as the core material for pump bodies is due to theirexcellent structural stability and chemical stability. This choice minimizesthe risk of contamination when in direct contact with liquid medications. Theceramic materials selected for ceramic metering pumps are primarily composed ofadvanced industrial ceramics such as aluminum oxide, zirconium oxide, or othersingle crystal structure materials. Typically, the purity of the raw materialsexceeds 99.5%, and the manufacturing process, crystal structure, and variousperformance indicators of the materials are reproducible. These materialcharacteristics ensure that ceramic components manufactured with them exhibithigh stability and controllability of risks throughout the product's lifecycle.This is fundamentally different from the ceramics we encounter in our dailylives. Common household or artistic ceramics are typically made from a mixtureof silicate materials such as kaolin, quartz, and feldspar, which are fired athigh temperatures. Due to the uncertainty of their composition, these ceramicsexhibit poor chemical characteristics and process reproducibility. Theuniformity and stability of the material's crystal structure cannot beprecisely controlled through process design. As a result, ceramic components inthese products may experience unverifiable migration of chemical substances,wear resistance issues, and release of insoluble particles during actual usage,aspects that are challenging to validate in the product design phase.

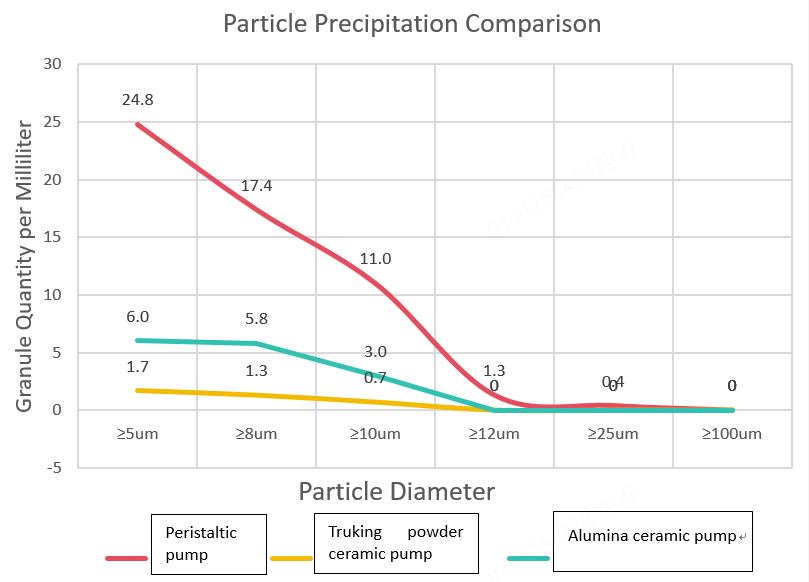

Accordingto the standards outlined in the 2020 edition of the Pharmacopoeia of thePeople's Republic of China, Section Four, page 126: the number of particlesequal to or exceeding 10 micrometers per 1ml must not exceed 25, and the numberof particles equal to or exceeding 25 micrometers must not exceed 3.

●The Key FactorsAffecting the Critical Performance of Ceramic Metering Pumps

Ceramic metering pumps, startingfrom the preparation of basic materials, involve a complex manufacturingprocess with numerous stages. Many factors influence the final performance ofthe product. The most critical factors can be summarized as follows:

1. Preparation of CeramicPowders: The ceramic powders used in the manufacturing process require theselection of high-purity aluminum oxide or zirconium oxide. This involvescontrolling particle size uniformity, press-friendly powder granulation, andother process steps. The prerequisite for manufacturing high-performanceceramic metering pumps is the preparation of ceramic granular powders withoutstanding sintering characteristics and controllable particle dispersion.

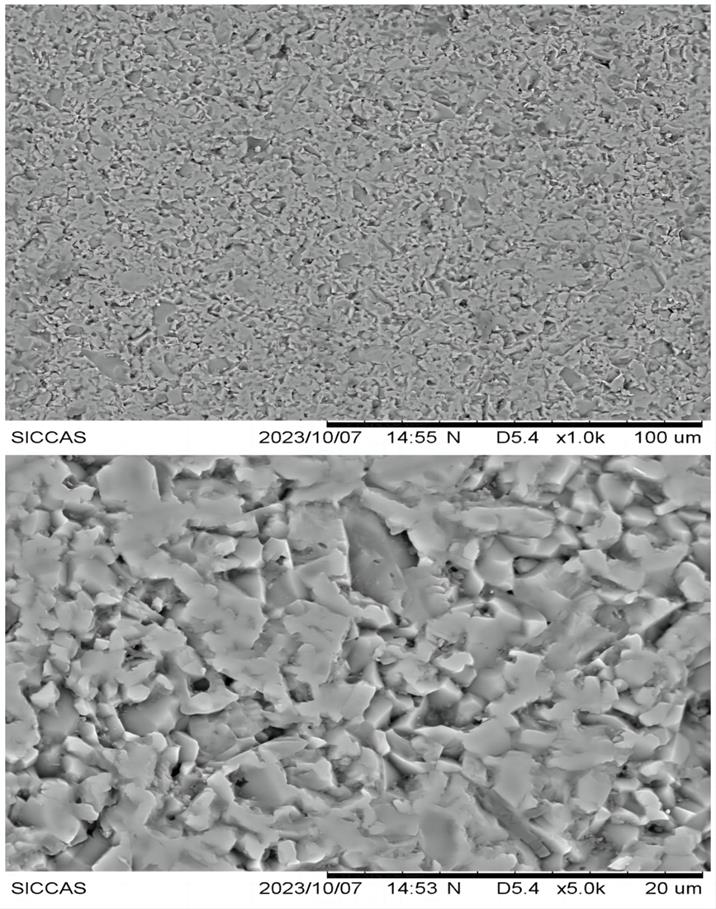

2. Reproducible Ceramic Blank ManufacturingProcess. The process of manufacturing reproducible ceramic blanks involves thecompaction and sintering of ceramic powder particles, ultimately yielding rawmaterials for the production of components in ceramic metering pumps. To ensurethe stable performance of subsequent components, it is imperative that theblanks possess several key characteristics: a dense microstructure, uniformgrain size, and consistent mechanical properties.

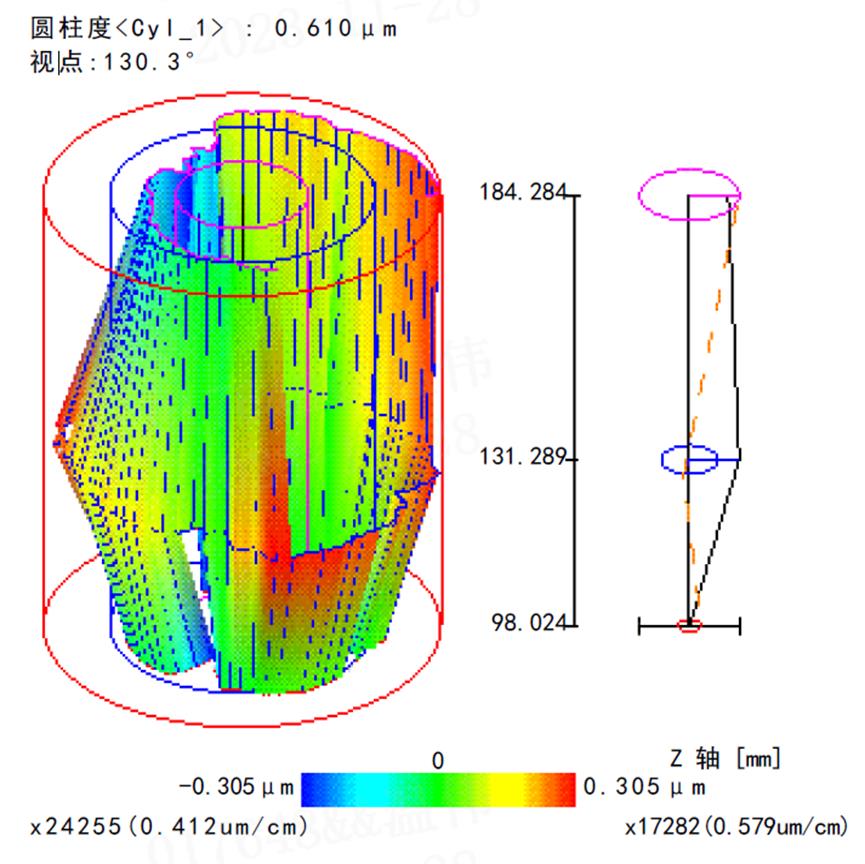

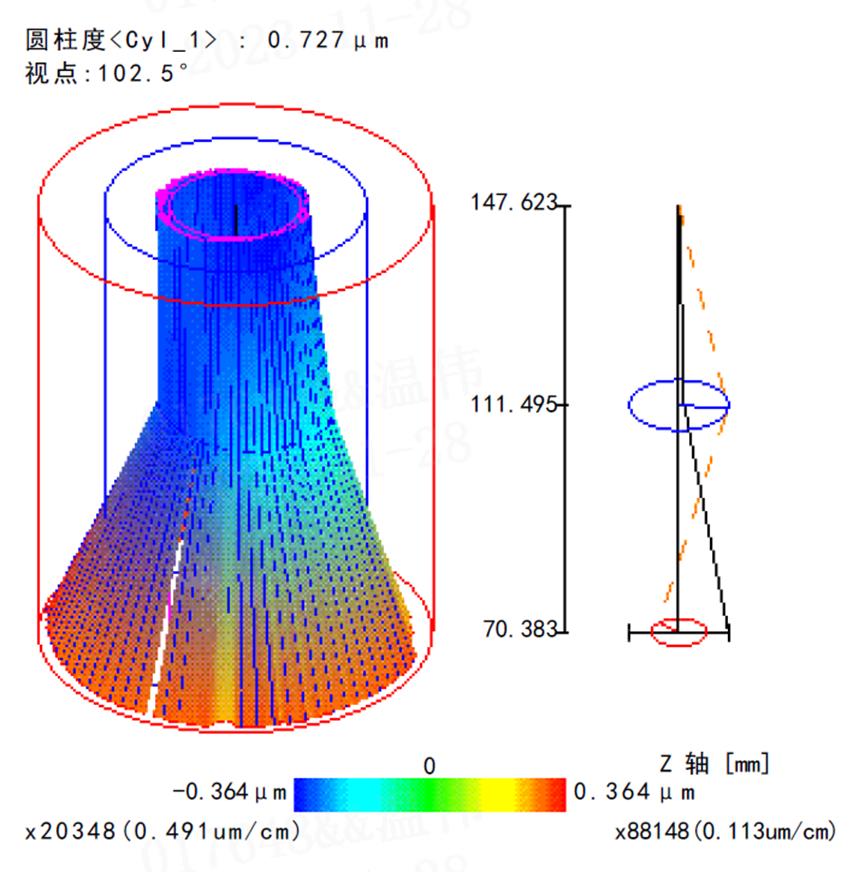

3.The precision control ofkey components in ceramic pump manufacturing is crucial. The inherent precisioncharacteristics of ceramic pumps dictate the necessity for ultra-high precisiontolerance control in the processing of critical parts such as ceramic plungersand ceramic pump casings. Tolerance clearances must be controlled within 5micrometers, cylindricality error kept below 0.8 micrometers, roundness errorless than 0.6 micrometers, and surface roughness (Ra) maintained at levelsbelow 0.4 micrometers.

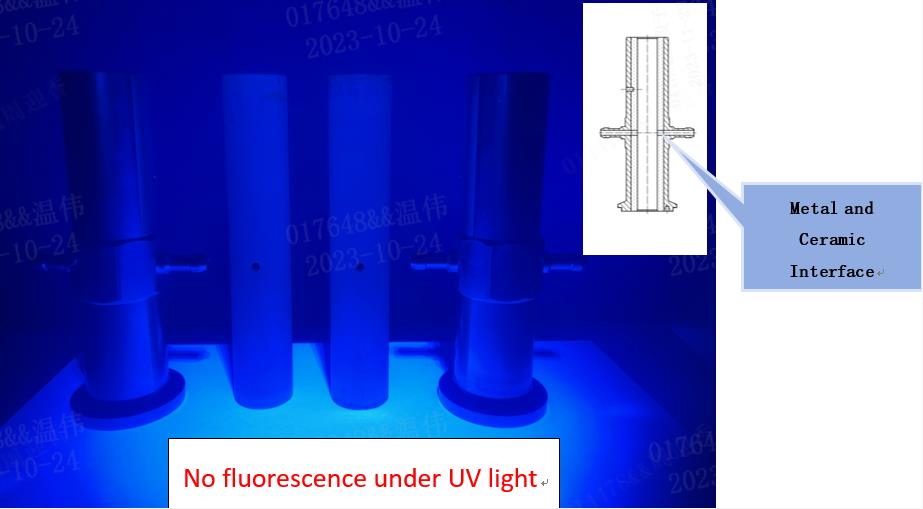

5. Design andVerifiability of Ceramic Metering Pump Structure. The structure of the ceramicmetering pump should ensure stable accuracy throughout its usage, ease ofcleaning and maintenance, and verifiability. The stability of the product'sstructure is achieved through a precision fit between the pump rod and metaljoint, as well as between the ceramic pump sleeve and the metal pump housing,ensuring no relative movement gaps and eliminating the risk of cleaningresidue. The inlet and outlet nozzles are seamlessly connected to the metalpump housing, eliminating the risk of liquid medication seepage. This is acrucial factor influencing the accuracy fluctuations and safety risksassociated with the use of ceramic metering pumps.

Truking Advanced Materials TechnologyCo., Ltd. takes GMP standards as the core philosophy for product design andquality management. Centered around validated design, the company engages inthe development of ceramic metering pumps. The main aspects of the validationdesign for ceramic pumps include precision filling validation, physicochemicalproperty validation of materials, consistency validation of ceramic pumpstructure dimensions, risk validation of migration of material constituents inliquids, validation of insoluble particles in ceramic pumps, and reliabilityvalidation of the cleaning process for ceramic pumps.

Truking Advanced MaterialsTechnology Co., Ltd. deeply understands the risk control and usage requirementsof pharmaceutical ceramic metering pumps for customers. In collaboration withwell-known domestic universities, research institutions, and top-notch asepticfilling technology teams at home and abroad, the company introduces advancedprecision ceramic manufacturing technology from Europe. From powder preparationto precision processing and validated design, Truking explores innovativedevelopments in product technology and manufacturing technology for ceramicmetering pumps. The goal is to create high-precision, highly reliable, highlyverifiable, and low-risk ceramic metering pump products. The company's missionis to provide customers with the most cost-effective ceramic pump fillingsolutions.